BLOGG

-

Skilningur á extrusion mold: burðarás nútíma framleiðslu

Inngangur Extrusion mótun er lykilferli í nútíma framleiðslu, sem gerir kleift að búa til samfelld form og snið með nákvæmni og skilvirkni.Þetta blogg kafar ofan í ranghala útpressunarmóta, kanna sögu þeirra, notkun...Lestu meira -

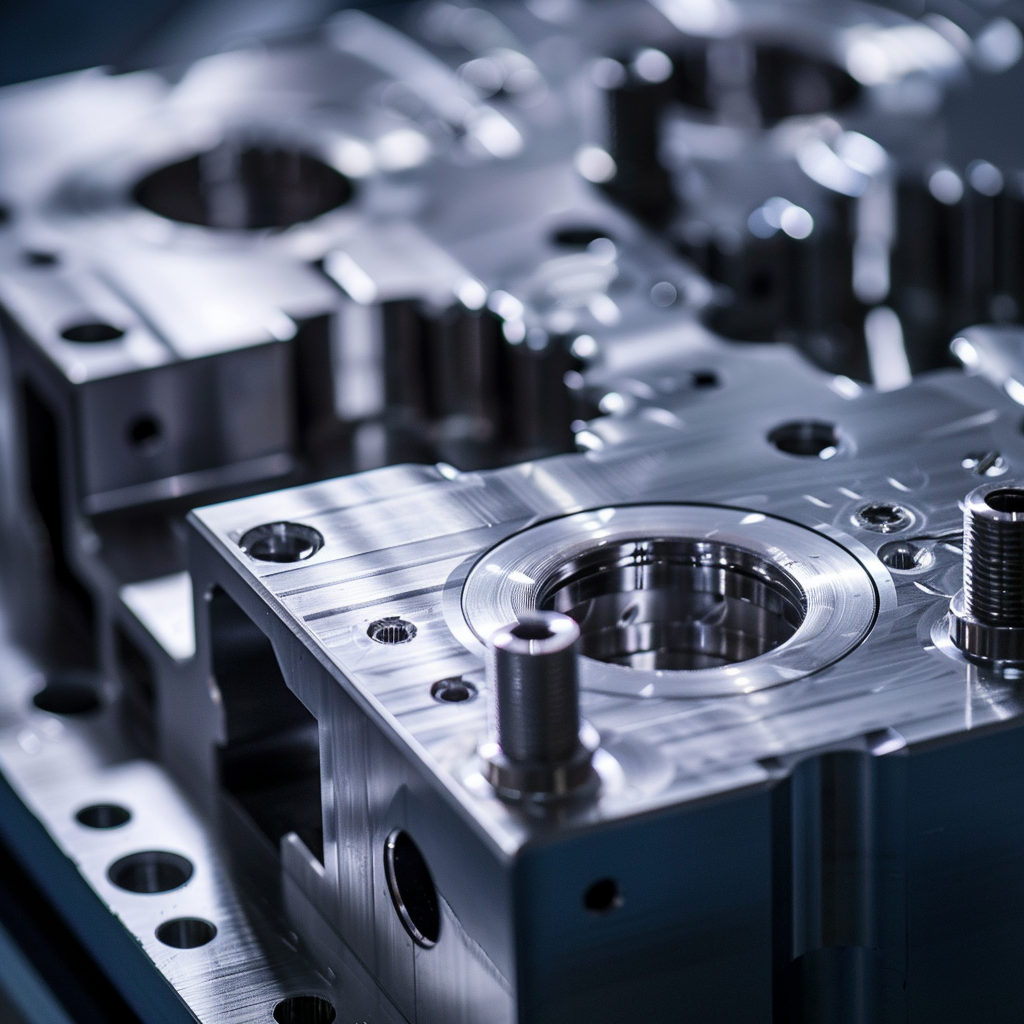

Mikilvægi og viðhald sprautumóta í framleiðslu

Sprautumót skipta sköpum í framleiðsluferlinu, sérstaklega til að framleiða nákvæma plasthluta.Ending og líftími þessara móta hefur bein áhrif á framleiðslu skilvirkni og kostnað.Vel viðhaldið mót getur framleitt hundruð þúsunda hluta, sem gerir...Lestu meira -

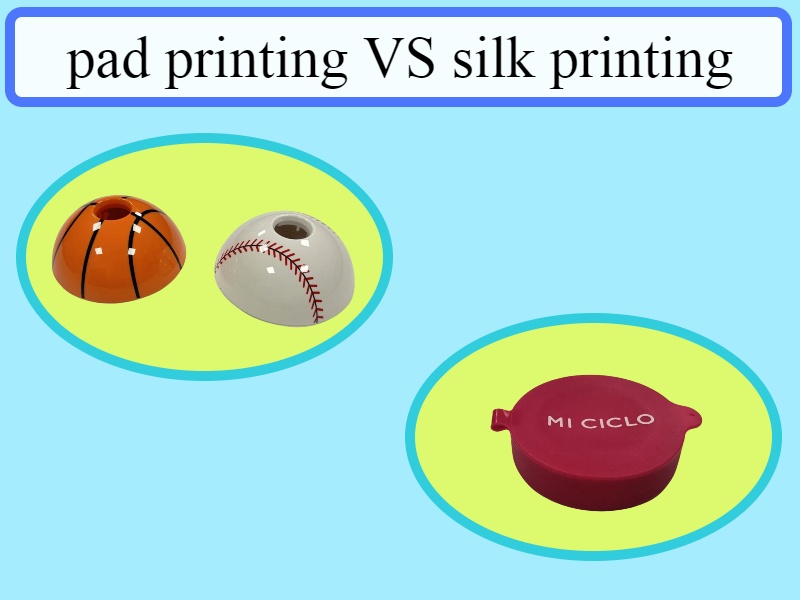

Munurinn á mater leturgröftur og púðaprentun

Forskriftir og upplýsingar núverandi vara eru orðnar ómissandi hluti.Flestir framleiðendur munu grafa upplýsingarnar á vörurnar með silkiskjáprentun, púðaprentun eða málmgröftur.Hins vegar skilurðu virkilega kosti og d...Lestu meira -

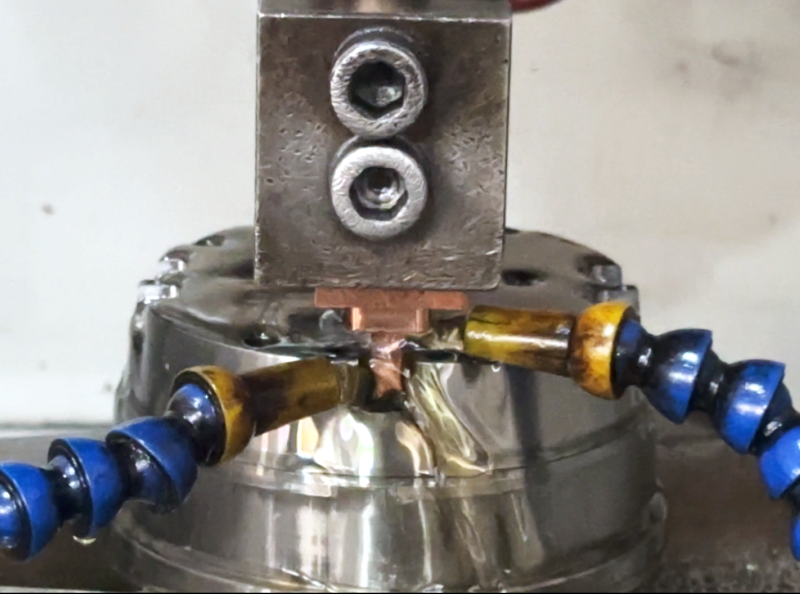

Rafneistameðferð í mygluvinnslu

Í dag ræðum við um rafneistaútfellingu í málmblöndur, á sama tíma munum við einbeita okkur að þessari tækni hvernig á að breyta moldinu í sprautumótunarverkfærum og steypumótum.Hvað er Electro-Spark Deposition?...Lestu meira -

Hvernig á að velja á milli sprautumótunar og CNC vinnslu

CNC og Injection sem tvö eru vinsælustu handverkin til framleiðslu, sem bæði geta búið til hágæða vöru eða hluta á hverju svæði og þeir hafa sína kosti og galla.Svo hvernig á að velja bestu leiðina fyrir verkefnið getur verið áskorun.En sem atvinnumaður...Lestu meira -

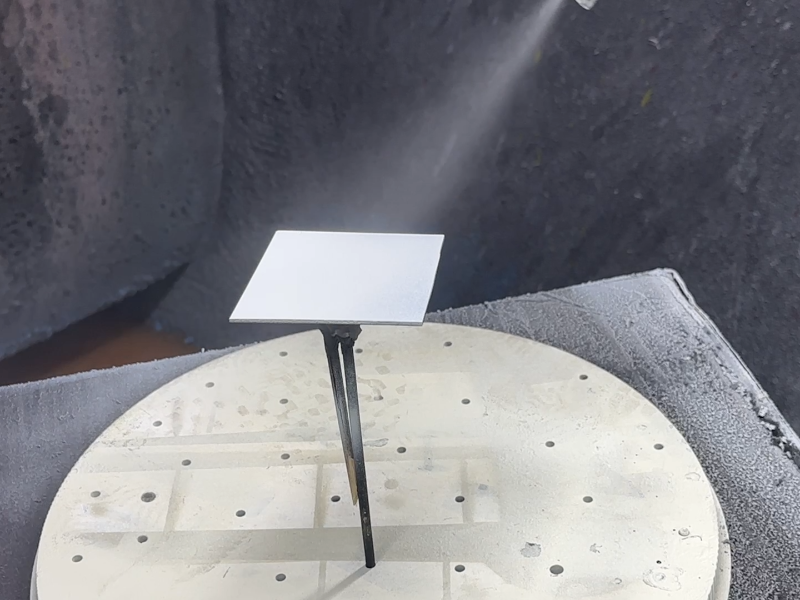

Hvernig á að búa til heilsu, öryggi og hreint lækningatæki

Þegar kemur að lækningatækjum er hreinlæti, öryggi mikilvægt.Öll lækningatæki, hvort sem þau eru einnota, ígræðanleg eða endurnotanleg, verður að þrífa meðan á framleiðslu stendur til að fjarlægja olíu, fitu, fingraför og önnur aðskotaefni í framleiðslu.Endurnýtanlegt pro...Lestu meira -

Að skilja muninn á púðaprentun og skjáprentun

Púðaprentun og skjáprentun eru tvær mismunandi prentunaraðferðir sem eru notaðar á margs konar vörur og á margs konar mismunandi efni.Skjáprentun er notuð á textíl, gler, málm, pappír og plast.Það er hægt að nota á blöðrur, límmiða, fatnað, læknis ...Lestu meira -

Silkiprentun í tísku og heimilisskreytingum vöruv

Hvað er silkiprentun?Skjáprentun er að þrýsta bleki í gegnum stensilskjá til að búa til prentaða hönnun.Það er víðtæk tækni sem er mikið notuð í mismunandi atvinnugreinum.Ferlið er stundum kallað skjáprentun eða skjáprentun, en þessi nöfn eru nauðsynleg...Lestu meira -

Leiðbeiningar um aðferðir við sprautumót eftir vinnslu

Eftirvinnsla eykur eiginleika sprautumótaðra plasthluta og undirbýr þá fyrir fyrirhugaða lokanotkun.Þetta skref felur í sér úrbætur til að útrýma yfirborðsgöllum og aukavinnslu í skreytingar- og hagnýtum tilgangi.Í RuiCheng, bls...Lestu meira -

Hvað er púðaprentun

Púðaprentun, einnig þekkt sem tampógrafía eða tampoprentun, er fjölhæf óbein offsetprentunartækni sem notar kísillpúða til að flytja tvívíddar myndir frá leysigrafinni prentplötu yfir á þrívídda hluti.Þetta ferli gerir prentun á...Lestu meira -

Málmur eða plast: Hver er munurinn?

Þegar kemur að því að búa til vöru getur valið á milli plasts og málms verið erfitt.Bæði efnin hafa sína einstaka kosti, en þau deila líka nokkrum furðulíkum.Til dæmis geta bæði plast og málmur boðið upp á hitaþol og styrk, m...Lestu meira -

Eitthvað sem þú þarft að vita um TPU sprautumótun

Tpu innspýtingÞað eru ýmsar aðferðir við TPU mótunarferli: sprautumótun, blástursmótun, þjöppunarmótun, útpressunarmótun osfrv., þar á meðal er sprautumótun algengust.Hlutverk sprautumótunar er að vinna TPU í nauðsynlega hluta, sem er skipt...Lestu meira