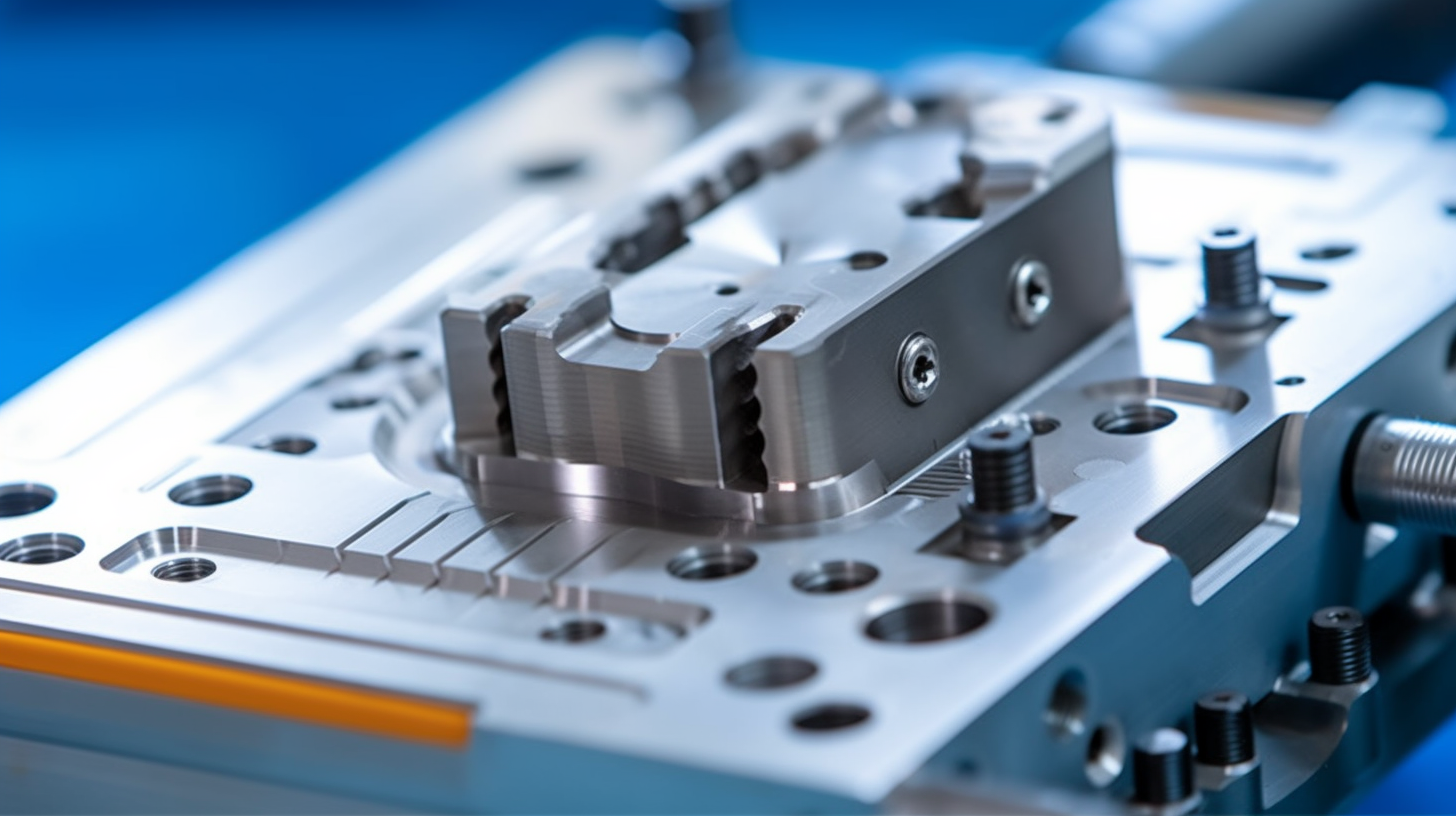

Draft angles are one of the most critical yet often overlooked elements in injection molding. A draft angle is a slight taper applied to the vertical walls of a molded part to facilitate smooth ejection from the mold. Without proper draft angles, parts can stick to the mold, leading to defects, surface damage, and increased production costs.

Let’s explore how draft angles impact part quality, mold longevity, and manufacturing efficiency.

Why Are Draft Angles Essential in Injection Molding?

Draft angles allow molded parts to release smoothly from the mold by reducing friction and ejection force. When plastic cools, it shrinks slightly and adheres to the mold cavity. If the walls are completely vertical, the part may resist ejection, causing scratches, warping, or even mold damage.

Key benefits of draft angles:

Prevents Sticking: Reduces friction between the part and mold cavity.

Improves Surface Finish: Prevents drag marks or defects during ejection.

Extends Mold Life: Reduces stress on the mold, minimizing wear and tear.

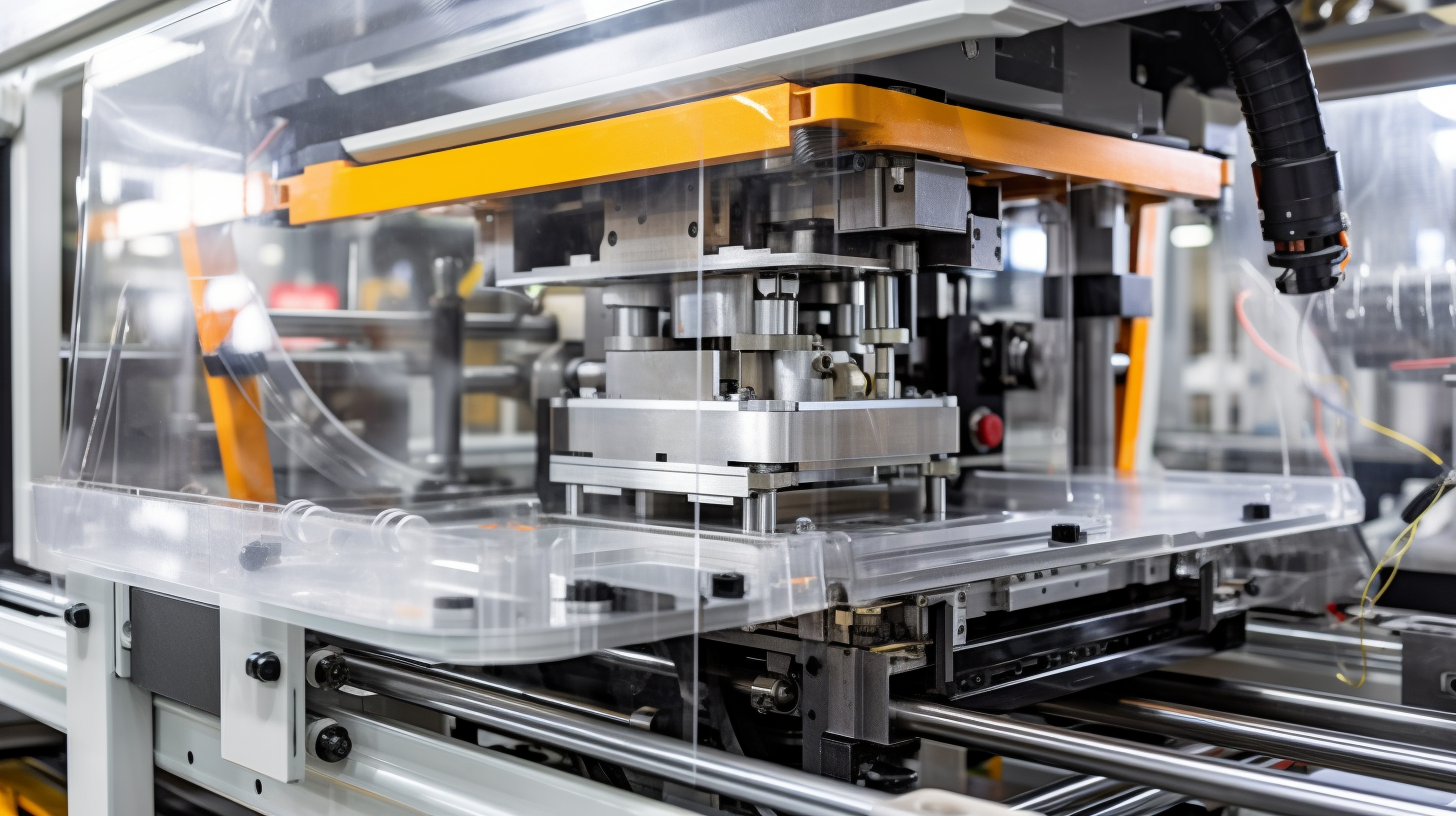

Enhances Production Efficiency: Reduces cycle times by making ejection easier.

How Do Draft Angles Affect Part Quality?

Proper draft angles ensure high-quality molded parts with smooth surfaces and precise dimensions. Parts with insufficient draft are more likely to suffer from cosmetic defects such as scuff marks, or even structural issues due to improper ejection.

For textured surfaces, draft angles become even more critical. The deeper the texture, the larger the draft angle needed to ensure the part releases cleanly without damaging the finish.

Best Practices for Designing Draft Angles

To optimize draft angles in injection molding, consider the following:

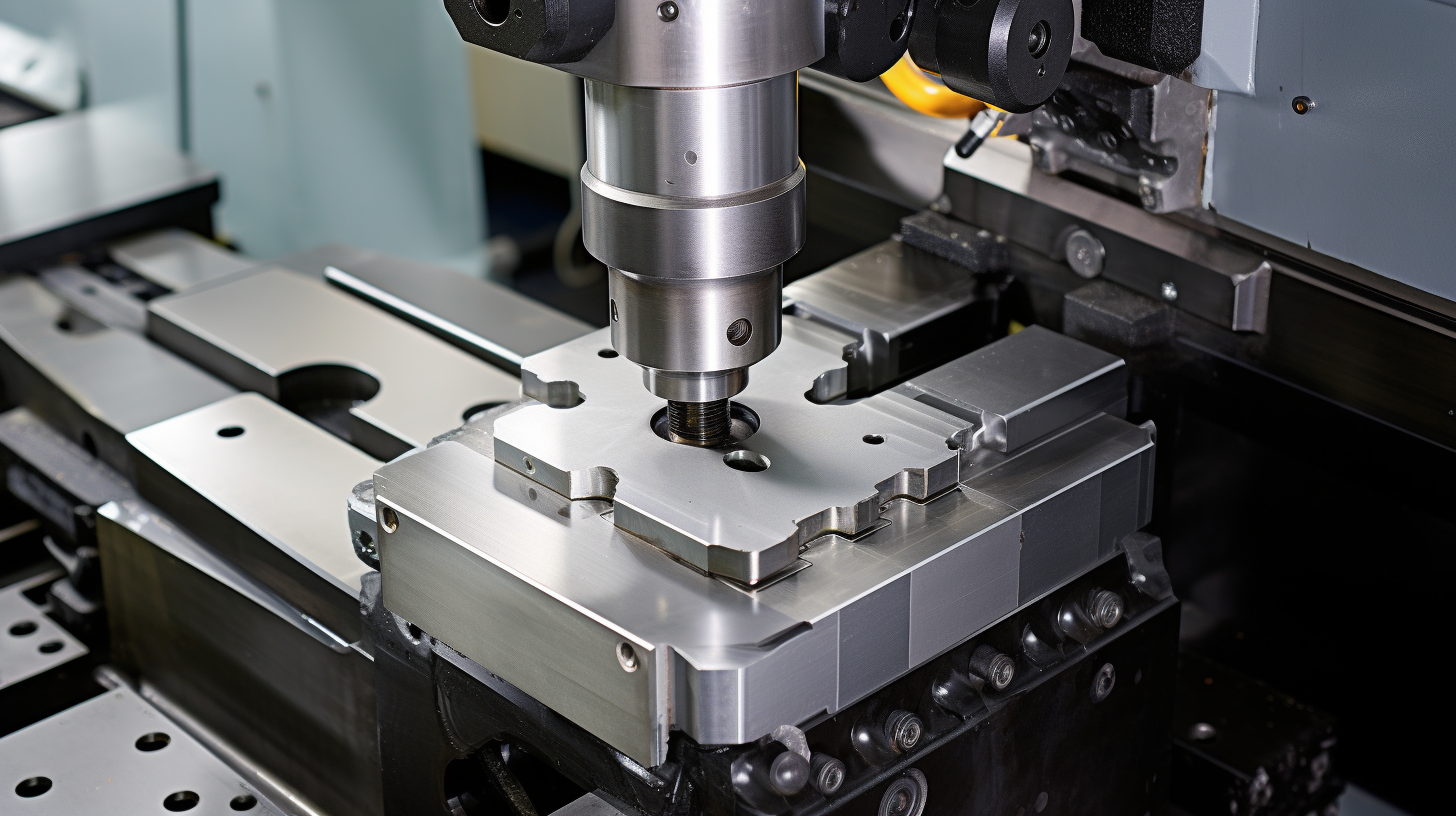

Standard Draft Angle: A minimum of 1° per side is recommended for smooth surfaces, while textured parts may require 3° to 5° for proper release.

Material Considerations: Some materials shrink more than others, requiring larger draft angles. For instance, ABS may need more draft than polypropylene.

Mold Complexity: Deep cavities or parts with undercuts should have greater draft to ensure easier ejection.

Comparison of Draft Angle Recommendations

| Surface Type | Recommended Draft Angle |

| Smooth Surface | 1°–2° |

| Lightly Textured Surface | 2°–3° |

| Deep or Heavy Texture | 5° or more |

How Do Draft Angles Extend Mold Life?

Proper draft angles reduce wear and tear on the mold by minimizing ejection force. Without adequate draft, excessive force is required to remove parts, leading to damage over time. This increases maintenance costs and shortens the mold’s lifespan.

By designing parts with appropriate draft, manufacturers can:

Reduce the need for excessive ejector force.

Prevent premature mold damage.

Increase overall mold life and reliability.

Key Tips for Implementing Draft Angles

Account for Surface Finish: Increase draft angles for textured parts to avoid scuffing.

Consider Material Shrinkage: Adjust draft based on material shrinkage properties.

Use Prototyping & Simulation: Test different draft angles in CAD and molding simulation software before finalizing the design.

Maintain Consistency: Ensure all vertical walls have uniform draft angles for consistent ejection.

Conclusion

Draft angles play a crucial role in ensuring smooth part ejection, maintaining mold longevity, and improving part quality. By applying appropriate draft angles, manufacturers can prevent defects, reduce production delays, and extend the life of their molds.

For expert advice on designing injection-molded parts with optimal draft angles, visit our resource center or contact us. Let’s help you create flawless, efficiently produced parts!

Post time: Feb-07-2025